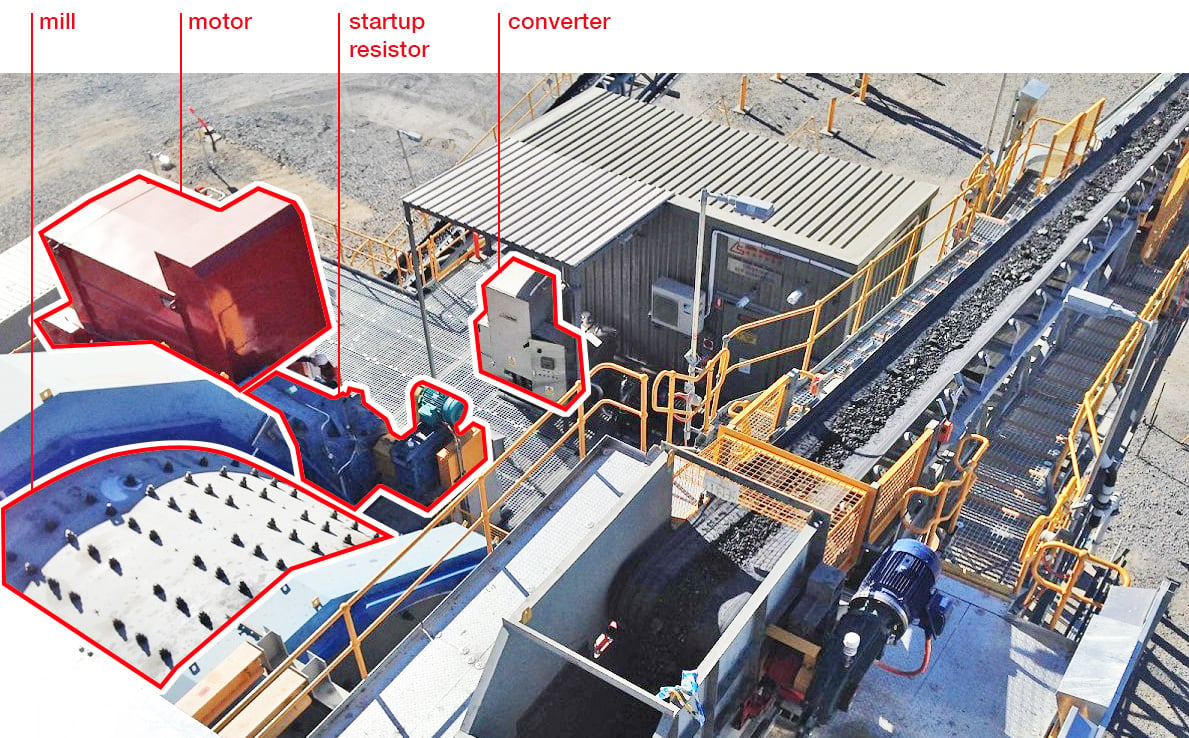

The case study featured here is a 3 MW doubly fed induction motor (DFIM) drive used for mining applications. The DFIM drive controls were designed, built, and tested by Indrivetec AG, at the request of CSE-Uniserve. Indrivetec AG is a Zurich-based power electronics, drives, and energy storage company and is an early adopter of Hardware-in-the-Loop (HIL) technology with a research lab primarily based on HIL for control design and testing.

The stator of this motor is connected to the medium voltage grid, and the rotor is connected to a liquid resistor of the system integrator CSE-Uniserve and an Indrivetec Insulated-gate bipolar transistor (IGBT) converter. Here, the resistor is used for starting and running at a constant speed, while the converter is used for variable speed operation.