.png?width=1920&height=1080&name=Spotlight%20Q%26A%20-%20Hitachi%20ABB%20Power%20Grid%20(final).png)

Blog Highlights

-

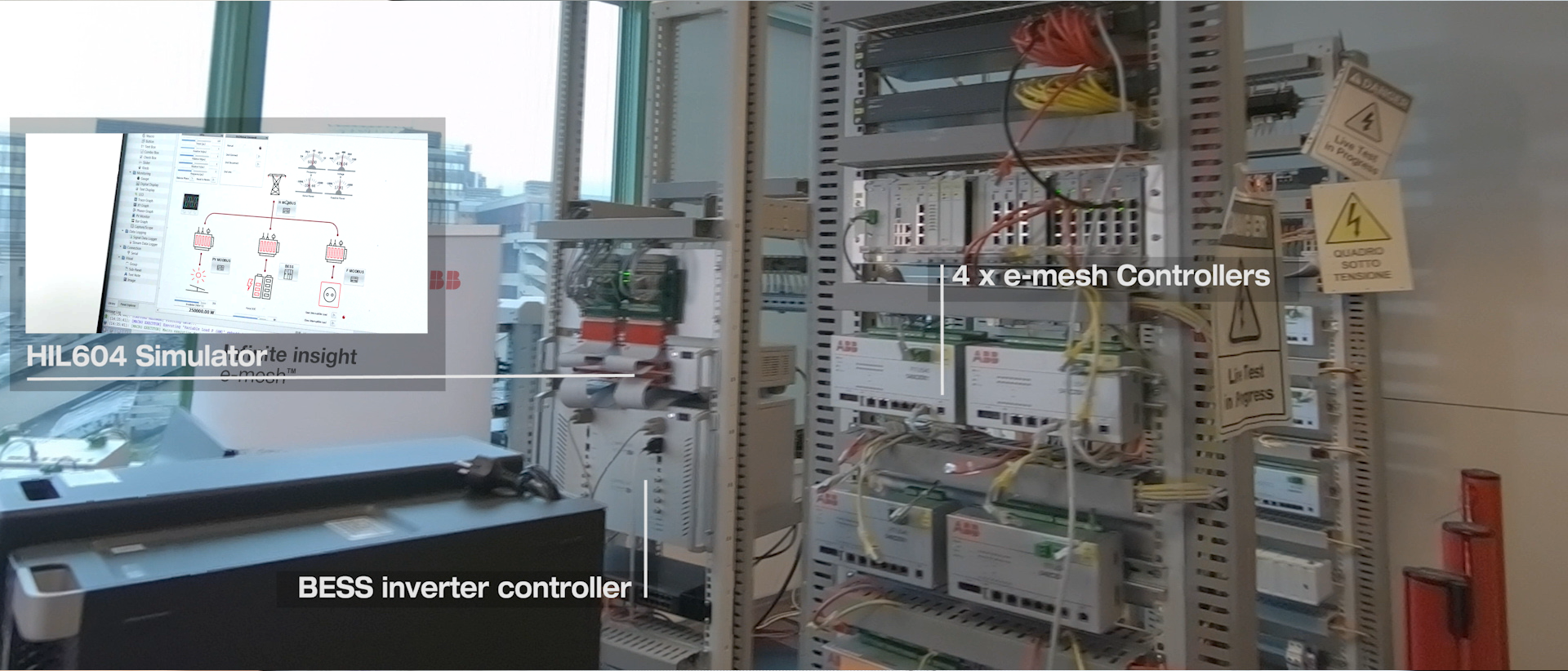

Hitachi Energy need to integrate various DERs and control multiple loads in a complex system environment.

- Before HIL, Software in the Loop was used to develop control algorithms but a system using real controllers was needed to ensure the system works.

- Controller Hardware-in-the-Loop (C-HIL) gives grid flexibility and adaptability to cover many test cases at an appropriate fidelity.

- C-HIL can be used from the early design phase all the way into operational performance and customer demonstration with factory acceptance testing.

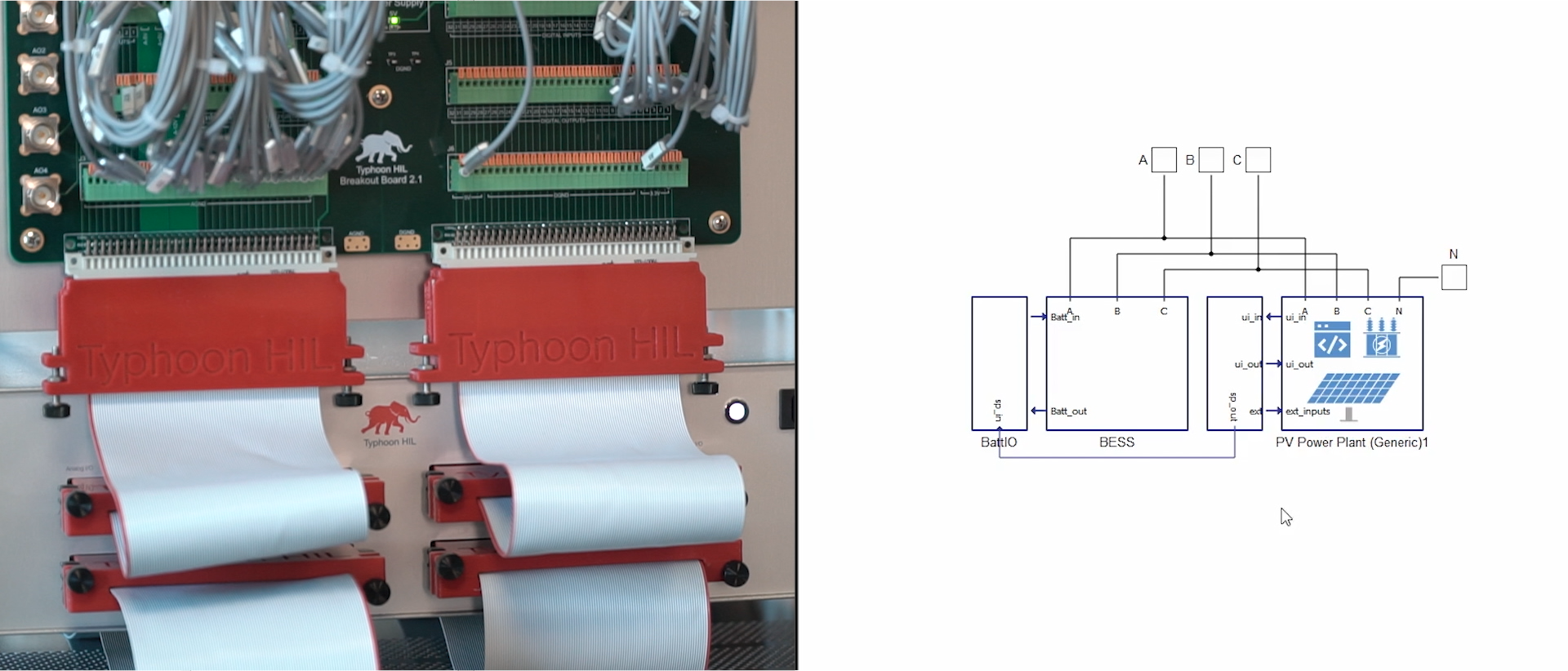

- For microgrids with BESS and solar PV, the seamless transition from grid-connected to islanded mode was demonstrated using C-HIL.

- “HIL Tested” for Hitachi Energy means great performance.

In this next Industry Spotlight Q&A session, we got a chance to speak with Tilo Buehler, the Global Product Manager for the Grid Edge Solutions team at Hitachi Energy.

Tilo Buehler has a multi-disciplinary background comprising activities from research on quantum electronic devices to engineering novel features of products in the electric power grid. He discusses the main benefits of using C-HIL technology to design and test the Hitachi Energy e-mesh control solution.

The Hitachi Energy e-mesh control solution is based on a robust, modular, and scalable remote terminal unit platform that is designed to manage the seamless integration of various distributed energy resources (DERs), traditional assets, and loads in a complex system environment.

What are the key challenges to designing and testing microgrid controllers?

At Hitachi Energy, we must integrate many DERs such as photovoltaic generators, battery energy storage, and control multiple loads. That means we need to interface a lot of controllers in a complex system environment and do so in a system environment that requires permanent changes.

So, we need to manage the complexity of changing systems and to do the development of those controller solutions in a cost-efficient and effective manner.

What did you use to design and test controllers before HIL?

Before we had the ability to use real-time simulations coupled to our hardware controllers, we would develop this system in a software environment.

The SIL environment is the basic development tool to develop the algorithms that we will then implement on our controllers. But to ensure that the system works, we needed a system that uses the real controller of the devices in the field.

Now using C-HIL, we have much greater test case coverage at an appropriate fidelity to test the solutions in a system environment with a lot more versatility and flexibility to adapt to the system environment.

Can you describe C-HIL?

C-HIL is basically the combination of real hardware controllers with a computer simulation of the behavior of the power system. To demonstrate the capability of the system, the C-HIL is an excellent tool because we can show the real performance of our controllers. And how the system will respond to basically the control concept that we have developed. We can then show the customer that the system works before we can deploy it on the real site.

What are the main advantages of a C-HIL system?

The controller HIL system gives us grid flexibility and adaptability to cover many test cases. We can get good test coverage of the system behavior before we install it and thereby have good confidence that the control solution we have developed will work in the real plant scenario.

We can also cover a significant timescale in the real-time simulations of the system behavior. We can start from sub-millisecond timescales that are required for the dynamic behavior of individual devices. And we can integrate this with the tens of millisecond timescales that are required for a larger power system behavior.

“We could also work with very good support from Typhoon HIL in getting the system set up and operational in a very short amount of time.

Tilo Buehler

Global Product Manager

Grid Edge Solutions at Hitachi Energy

At what stage of the product lifecycle do you use a C-HIL system?

We use C-HIL from the design phase of the project all the way into the operational part, ensuring that we can do performance validation or verification in the first step, but then also operational performance optimization in the operational part of the system.

We can also use the tool for customer demonstration purposes to show to the customer that the product they have purchased performs according to their expectations. And this is usually done by demonstrating the real product performance. And given that not all the system environments can be realized in a factory acceptance test, using the C-HIL again gives this wider coverage in the test cases that can be shown and can be demonstrated.

Can you give an example of a test scenario that is important to show to your customers?

We can run battery energy storage together with photovoltaic generation in a microgrid so that the system can run when it is connected to the rest of the grid, but it can also run when it is being disconnected from the system. The seamless transition from a grid connected mode of operation to an islanded mode requires specific control functionalities to be implemented in the controller. And the controller hardware in the loop allows us to demonstrate this capability.

What does HIL tested mean to you?

HIL Tested means great performance.