As Europe’s premiere research and technology organization, the Austrian Institute of Technology (AIT), bridges the gap between industry and research by utilizing innovative solutions to key infrastructure issues.

Zoran Miletic, Senior Research Engineer and Power Electronics Design specialist at AIT, talks about how AIT developed its powerful pre-certification toolbox to design and test smart grid converters for grid code compliance using controller Hardware-in-the-Loop (C-HIL) technology.

Growing Complexity of Grid Codes Requires Optimal Testing Process.

What does HIL tested mean for AIT’s smart grid converter controllers?

Zoran: Hardware-in-the-Loop technology enables more in-depth testing and test coverage than testing in a physical lab setting.

The whole process of lab testing becomes painstaking and complicated in terms of safety when high-power and hazardous voltage levels are present.

Hardware-in-the-Loop technology allows testing in a safe environment –at a cozy office desk—with the same confidence in test results as testing in the power lab.

How do new grid code requirements for smart converters affect control development and testing?

Zoran: Simply, new features and requirements are continually evolving and requiring more detailed testing of smart inverters in general.

How AIT and Sandia National Lab developed a Smart Grid Converter for grid code compliance

At the same time, there is growing pressure for business stakeholders to get certified and release certified products to get faster time to market. And HIL-based pre-certification ensures faster time to market.

At what stage in your development process did you use Hardware-in-the-Loop technology?

Zoran: Hardware-in-the-Loop testing came quite handy in all aspects of the development process: controls development, testing, validation, software integration and pre-certification in the end.

In other words, our development process is entirely dependent on Hardware-in-the-Loop technology.

HIL Pre-certification Test Data Matches Lab and Field Test Data.

Can you give an example of grid functions that need to be tested for grid code compliance?

Zoran: One of the most challenging parts of certification testing is testing of low voltage ride through (LVRT) requirements for inverter compliance. In our SmartTEST lab, we were able to recreate real LVRT and short-circuit events according to certain standards.

Then we compared the lab test results with controller Hardware-in-the-Loop test results and saw quite a close match.

If a unit under test passes some LVRT event in a C-HIL environment, then the likelihood of passing is almost certain in terms of control behavior.

Accelerate Control Development and Testing for Grid Code Compliance.

How did Hardware-in-the-Loop accelerate control development and certification?

Zoran: With test automation, we were able to cut time in pre-certification and time to market.

For example, lab testing of certain LVRT requirements takes days but with automated C-HIL testing, it takes minutes to complete the tests.

Although lab test data is still necessary for inverter certification, the probability of getting certified is almost certain with C-HIL pre-certification.

More Test Coverage without Lab Infrastructure Costs.

Can you tell me more about how HIL enables greater test coverage than testing in a power lab?

Zoran: Not all tests are possible in the lab because the lab might not have all the equipment needed. For example, there is a PV simulator block or low voltage ride-through container in Typhoon HIL. And not all the manufacturers have these facilities because of large capital investments needed.

.jpg?width=1697&name=Inverter%20Interoperability.Still001%20(2).jpg)

Model Microgrids and Test for Interoperability.

How were you able to use HIL technology to model microgrids?

Zoran: For a microgrid set up, we were able to model battery storage, PV, as well as variable load and interconnection to a grid –all in one system. We also used HIL for testing interoperability or connectivity of different components.

Our converter is SunSpec compliant and supports other connectivity options like IEC61850. As HIL natively supports some of this connectivity, we were able to test all of that on the HIL platform.

Click here to learn how to configure your HIL device to communicate with SunSpec Modbus

For a microgrid application, what test scenarios can you do more easily with HIL?

Zoran: Test scenarios like black outs are difficult to cause in a lab environment where the rest of the equipment is connected to the same grid. We can isolate and disconnect a portion of the equipment, but it's so much handier to do it in the HIL environment.

Also for black start capability, we can test converters forming a grid, and then connecting to the rest of the grid much easier in a HIL environment.

.jpg?width=1906&name=AIT%20HIL%20SCADA%20Custom%20UI.Still004%20(2).jpg)

HIL is Simply Plug and Play.

What has been the most surprising aspect of using Hardware-in-the-Loop technology based on your experience?

Zoran: Most surprising was fidelity or accuracy of real-time simulation. It is simply plug and play. If the model is done correctly and compiled into HIL, then it just runs. As simple as that.

And one word to describe your experience with HIL technology?

Zoran: Awesome.

The AIT has about 1.300 employees - mostly based at the main facilities Vienna Giefinggasse, Seibersdorf, Wiener Neustadt, Ranshofen and Graz – working on the development of the tools, technologies and solutions for Austrian industries that are of utmost relevance for the future.

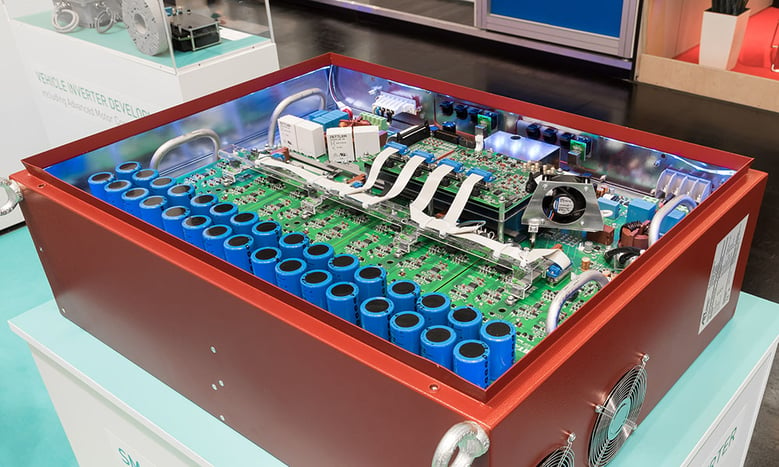

.jpg?width=779&name=AIT%20converter.Still004%20(2).jpg)