This article is the second in a series from the Microgrid Conference Panel 2019 – Making Sure Your Microgrid Will Work: Risk Reduction with Controller Hardware In the Loop (C-HIL) and Model-based Engineering

Qiang Fu, Regional Technology Manager at Eaton, was one of the panelists at the special session. He leads a research team to identify, develop, and validate technologies including microgrids, renewable energy, and power conversion.

He talked about the key challenges model-based system engineering and controller Hardware-in-the-Loop solves for microgrid development.

Key Challenges for Microgrid System Integrators

Fu mentions some major challenges power system integrators face when designing and testing complex power systems.

Optimize Microgrid Control Performance - Energy from renewable energy resources (DERs) are continually fluctuating and difficult to control. And it’s crucial to add other assets like energy storage, diesel generators and natural gas generators to control this intermittent power generation. Adding more pieces into the microgrid energy mix makes it very difficult to optimize controls for various DER components.

Expensive and Risky Lab Testing - As the electric power industry is moving towards high-power systems, it becomes more expensive to build lab infrastructure to test these megawatt systems. It’s also risky for engineers to test in the lab with high-voltage power that can damage equipment.

On-site Engineering Costs - On-site engineering costs due to lack of extensive testing or validation before commissioning can be very expensive. Fixing errors after commissioning requires a lot of engineering effort. And loss for the customer when business shuts down due to a power outage or maintenance down time.

Reusable or Repeatable Models -Microgrid applications engineers design customized models that are specific to the microgrid's application and site installation. Microgrid models are difficult to reuse due to varying dynamics, electrical performance, and communication protocols and various specifications from multiple component vendors. And power systems engineers will have to design new microgrid models and choose among many microgrid component vendors with multiple specifications.

Winning New Microgrid Customers - System integrators can show the added value of their microgrid control functions to potential customers. This includes advanced controller functionalities that can pass all operating conditions. Or specific fault cases and transient events like unexpected disconnection from the grid. And other various operating conditions that are specific to an installation.

Photo: Panelists from Raytheon, Schneider Electric, SEL, Eaton, And EPC Power at the Microgrid Knowledge Conference 2019 breakout session - "Making Sure Your Microgrid Will Work"

The Role of Microgrids: Utilities vs. Microgrid Customers

Fu offers two different perspectives on the role of microgrids that are useful to microgrid developers when designing power systems.

For utilities, the primary concern is how microgrids can support the distribution system and achieve system stability as more DERs are added into the power system. To improve power distribution system stability, Fu adds,

“The utility is more interested in how the distributed resources can be indirectly controlled by them.

Fu mentions the demand response program as an example. Utilities can indirectly control microgrid DERs through participation in the ancillary market. By participating in this program, utilities can control loads in homes to balance the distribution systems.From the customer side or microgrid end-users, Fu mentions,

“They’re looking at how the microgrid can make the operation costs much lower, more stable and more resilient.

These various perspectives require sophisticated microgrid controller functionalities that allows participations in the ancillary market. And advanced controller performance to optimize various DERs and loads in the power system.

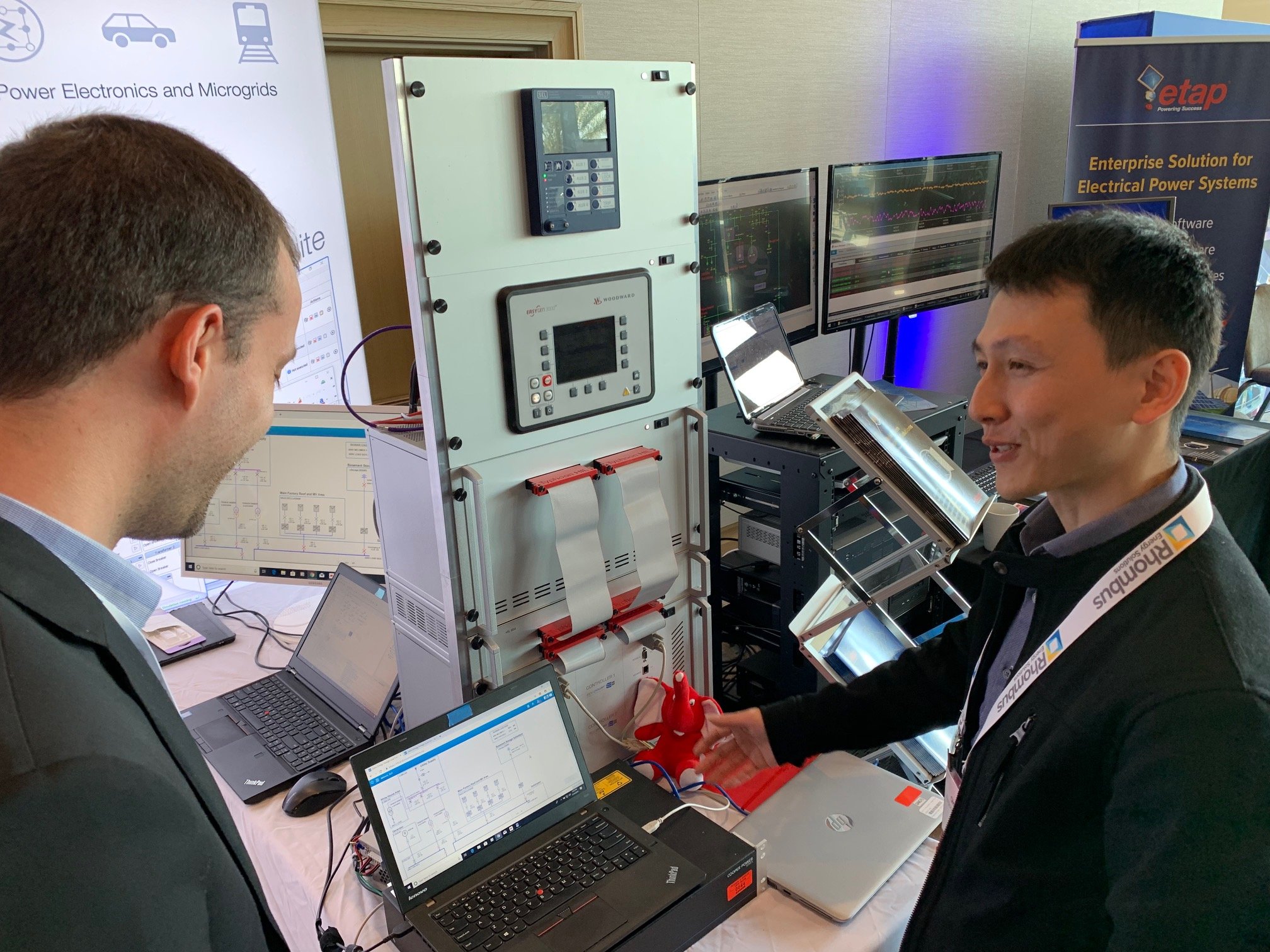

Photo: Qiang Fu and Murilo Almeida, Head of Microgrid Application at Typhoon HIL, in front of Typhoon microgrid testbed at the Microgrid Conference.

Stages of HIL Use in Microgrid Project Lifecycle

At what stage of the microgrid lifecycle does it make sense to use HIL? Fu outlines the stages of HIL use in previous microgrid projects at Eaton.

Stage 1: Technology analysis stage

This is a cost-benefit analysis to make the microgrid solution financially viable for clients. Based on this analysis, different designs are proposed.

Stage 2: Device Selection

Then the devices that will be used in the actual deployment are selected. This part can either augment the existing system or retrofit some of its components.

Stage 3: HIL Integration

The next step is to integrate that hardware into the HIL platform. Integrate the real microgrid controller, communication interfaces, and other devices for simulation.

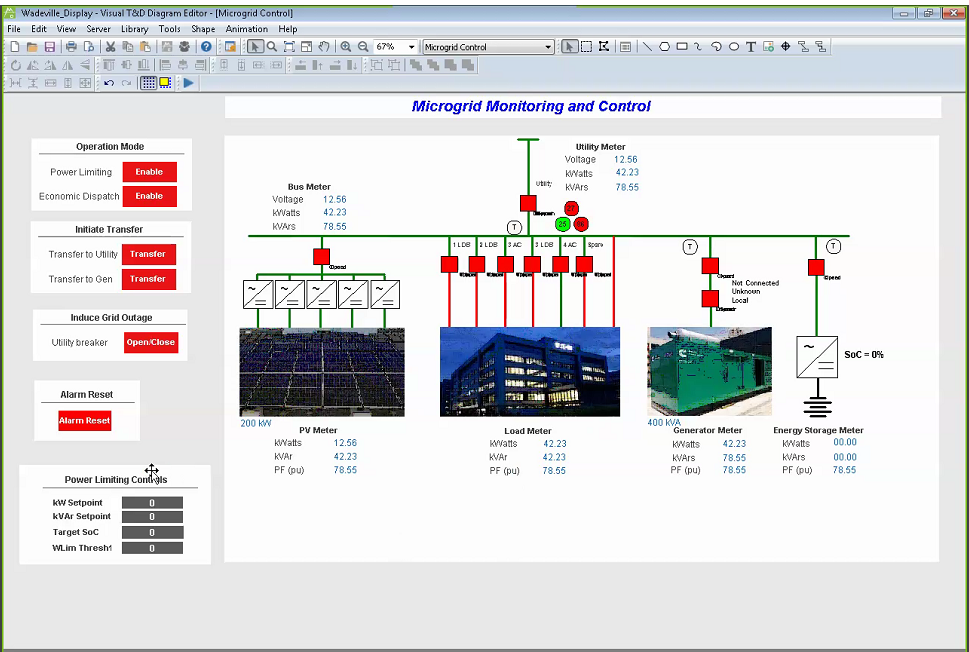

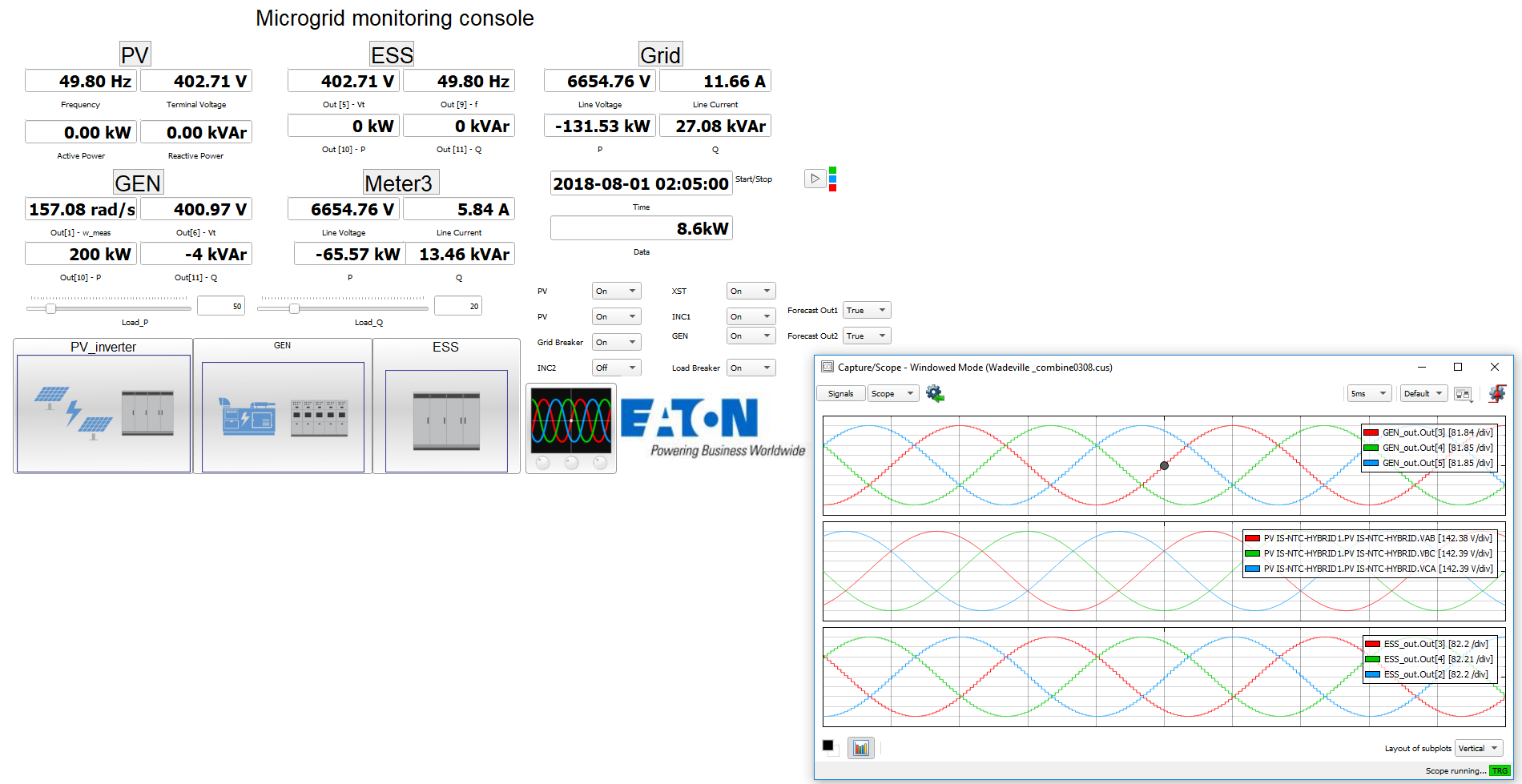

Photo: Eaton Microgrid Monitoring and Control with pv meter, load meter, generator meter and energy storage meter.

HIL Tested – Few Microgrid Controller Modifications

Since the actual devices are already integrated into the platform - the communication interface, automation functions and control functions - Fu says,

“After the HIL Test, you don’t need to make a lot of changes to the microgrid controller when you deploy it onsite because all the actual devices are integrated to the platform.

By testing the real controller and actual devices, there is little need to modify the microgrid controller when deploying on-site.

HIL Tested – Reduced On-site Engineering Costs

Fu emphasizes the pre-deployment validation of performance significantly reduces the level of necessary on-site engineering efforts, which tends to be the most costly and time-consuming.

“It really helps really reduce the engineering effort, engineering time as well as the cost.

His team can test unlimited operational scenarios in the controller Hardware-in-the-Loop platform compared to limited test cases on-site. High test coverage at high fidelity with the real controller in HIL, helps to significantly reduce the likelihood of on-site failures.

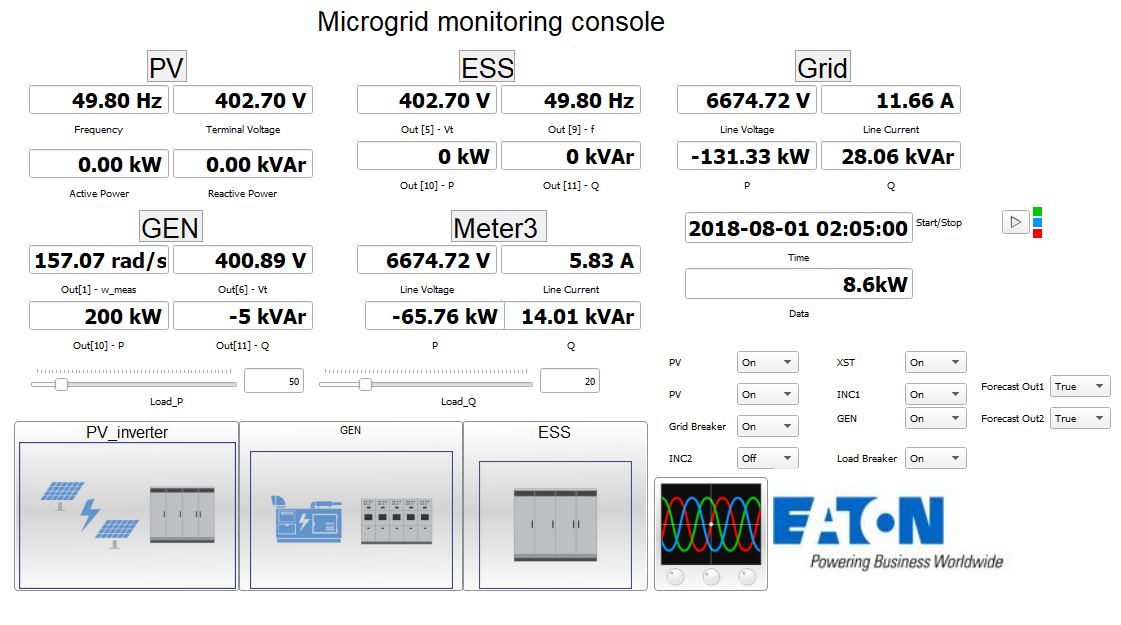

Photo: Eaton Microgrid controller demo with Typhoon HIL microgrid controller hardware-in-the-loop testbed

HIL Tested – Standard Modules for Future Microgrid Projects

Microgrids are developed for specific applications and custom requirements, making it difficult to reuse microgrid models due to varying dynamics, electrical performance, and communication protocols. And various specifications from multiple component vendors.

HIL can be provide standard models that can accelerate microgrid control design and testing. These standard HIL modules can be reused for future microgrid projects. And can be adapted to specific scenarios by changing model parameters.

HIL Tested – Safe and Effective Risk Mitigation

The HIL approach also provides safe and effective risk mitigation.

Engineers can safely debug controller firmware without the risk the of breaking the actual system by using dangerous high-power equipment for high-power converters.

Using HIL to test feasibility before implementation would safely avoid such scenarios.

HIL Tested– Win Microgrid Projects with Conceptual Demos

HIL not only saves engineering effort,but can also be a crucial platform to win customers.

Fu adds that HIL enables his team to quickly show the added value of their microgrid control functions to potential customers. This includes advanced controller functionalities that can pass all operating conditions. Or specific fault cases and transient events like unexpected disconnection from the grid. And other various operating conditions that are specific to an installation.

Photo: Typhoon HIL simulation capture/scope of Eaton microgrid model including PV, diesel genset and ESS.

Final Takeaway – One Tool from Design to Commissioning

An ideal scenario is to have a one-stop testing tool that can be used for the entire microgrid lifecycle. A digital twin that can run parallel to the actual system will be useful from design to commissioning and maintenance.

By collaborating with microgrid vendors, HIL companies can continually update existing vendor specifications so microgrid engineers can quickly simulate and evaluate power systems. Fu mentioned,

“If something can be abstracted and put in the HIL library, microgrid applications engineer can just load it up and see which controller to use.

With a microgrid library, microgrid applications engineers can quickly load abstract models, decide what controllers to use, and evaluate controller performance.

A real-time controller Hardware-in-the-Loop Microgrid Testbed can be the one tool to accelerate microgrid projects throughout the entire microgrid lifecycle.