Important lessons don’t always require big investments.

We see this in the Otis Air National Guard Base (ANGB) Microgrid Project at Joint Base Cape Cod, MA. It was named the 2019 Project of the Year for the DoD’s Environmental Security Technology Certification Program (ESTCP) on innovative technologies designed to improve energy security and increase power reliability at U.S. military installations.

The project involved a $5.7M investment from ESTCP, plus $1M from the state of Massachusetts, crafted to increase the utility of existing assets. Installation leaders and staff worked with Raytheon Technologies to integrate new battery storage and controls with existing wind generation resources to establish stand-alone (islanded) operational capability and to deliver $500k-$1M per year of value through time-shifting and frequency regulation services.

SERDP & ESTCP Webinar Series: Advancing Microgrid Solutions by Dave Altman, Raytheon Otis Microgrid principal investigator.

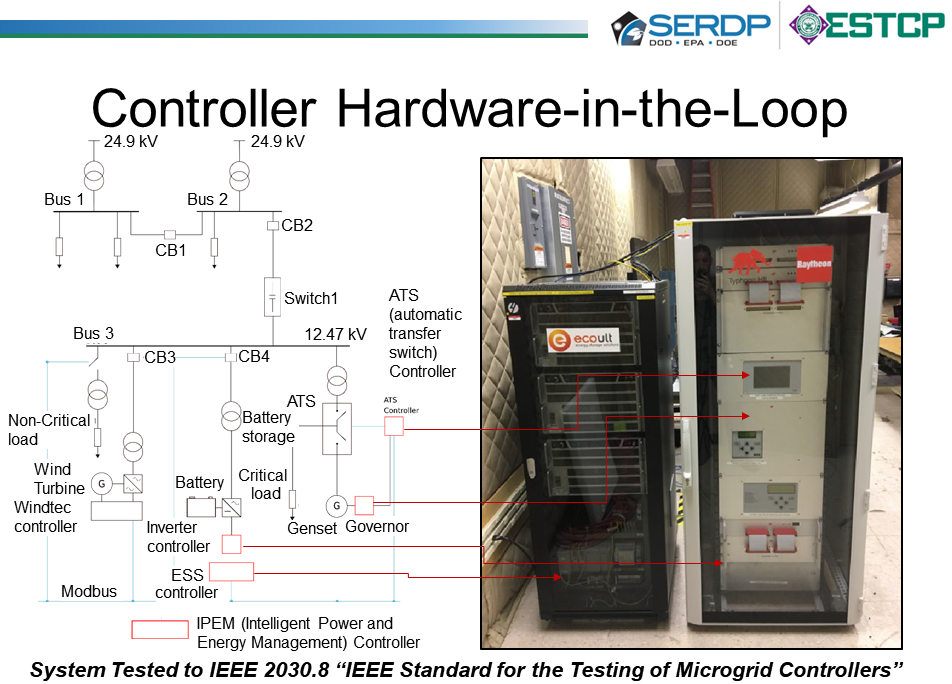

Controller Hardware-in-the-Loop

Raytheon Technologies, led by the principal investigator, Dave Altman used Typhoon-HIL’s Controller Hardware-in-the-Loop (C-HIL) solution to design and test the Raytheon Intelligent Power and Energy Management (IPEM) microgrid control system for Otis ANGB microgrid. This allowed the Otis ANGB microgrid to not only enhance its capacity to support its real-time intelligence missions but predict emergent behaviors that arise in complex system integration.

4 Key Lessons

Electricity, like most energy, has long been treated as a simple, undifferentiated commodity. New energy technologies and ways of thinking are helping us to turn the page; the Otis Microgrid Project offers a glimpse of such insights, including the following lessons:

1. Not all electricity has the same value.

Before this project was implemented, the previously installed wind turbine could produce up to 1.5 MW of electricity, or as little as zero – depending upon the weather. Worse yet, the wind resource could not contribute during grid outages, so it did not reduce the need for backup generators. Predicted wind turbine output had been valued the same as dispatchable grid power, but its real value (contribution to need) could not be controlled.

2. Smart Integration is the way to save money and build resilience.

The Otis project delivers power with much greater than average value by coordinating generation, storage, and control functions. With the right control protocols, the new Ecoult battery energy storage system (BESS) can be coupled with combustion generators and the wind resource to power mission-important capabilities, even in an islanded mode when grid power goes down. Under normal circumstances, the same system can time-shift power availability to help balance supply and demand and contributes to grid stability via service transactions with the New England Independent Service Operator.

3. Energy Digitalization leads to a smarter and agile future.

Legacy power systems were built of electromechanical devices - windings, magnets, and contacts – which were too slow, expensive, and inflexible to customized service. Digital sensors and communications have become capable and inexpensive, and many of today’s power electronic-based smart inverters, converters, controllers, and relays can respond and adjust in milliseconds, or even switch functions upon demand; some even make their own decisions. Such agility, of course, generates new opportunities for failure and surprise – which in turn increases the challenges and importance of trustworthy testing, preferably throughout system scoping, design, and operation.

4. Accelerated, iterative testing helps keep us safe and secure.

C-HIL testing increased system test coverage under a wide range of conditions – and enabled the prediction of emergent behaviors prior to installation. Typhoon HIL’s automated testing supports the extensive examination of system responses and the development of operating and response procedures. This system may have been the first microgrid to use C-HIL testing to satisfy IEEE Standard 2030.8.

Example test scenarios include the transition from grid-connected to islanded mode and transient scenarios. As power systems become more complex, dynamic, and intelligent, automated C-HIL testing will play an essential role in streamlining design and commissioning while reducing unanticipated operational situations.

Key Takeaways

The Otis Microgrid Project is not just a cost-effective initiative; it demonstrates how to create energy value and resilience through the forward-thinking and informed use of new digital power technologies.

The key benefits to the DoD include cyber-secure grid-interactive services, standby generators with “layered resilience” and operational benefits with sustainable capacity.

The project exemplifies new energy thinking and the use of emerging technologies to increase organizational capacity to anticipate, respond, recover, and adapt in the face of adverse events, change, and uncertainty – in other words, resilience.

How can you apply these in your own organization?