Introduction | The validation challenge for novel technology development

In our previous blog, we saw how HIL-powered digital twins are helping to accelerate the energy transition today by de-risking new product and operational strategies and bringing them to market faster. By using a single HIL model for both the developmental and operational stages of grid components, OEMs and grid owners have an easier time with identifying new ways to control existing grid components, characterize system responses with real data, and troubleshoot and resolve component failures both before and after they occur. Longer term research projects, however, pose another set of challenges altogether.

Developers working to bring novel and disruptive technologies to market often encounter a catch-22: installers and site owners at pilot sites often require demonstration of an operating system before they agree to live tests. This is particularly true for grid applications, where real power flows must constantly stay within safety limits to avoid damaging existing assets. When the specific business cases and capabilities of new assets and controls are still under development, how can developers make a plan to demonstrate to site owners that their product will work safely in a real case?

In the next sections, we’ll look at how HIL-powered digital twins of pilot sites are used in two separate European Commission funded research projects to benchmark, validate, and continuously improve new technologies and grid control strategies.

H2020 CREATORS | How do digital twins de-risk, speed-up and streamline creating Community Energy Systems?

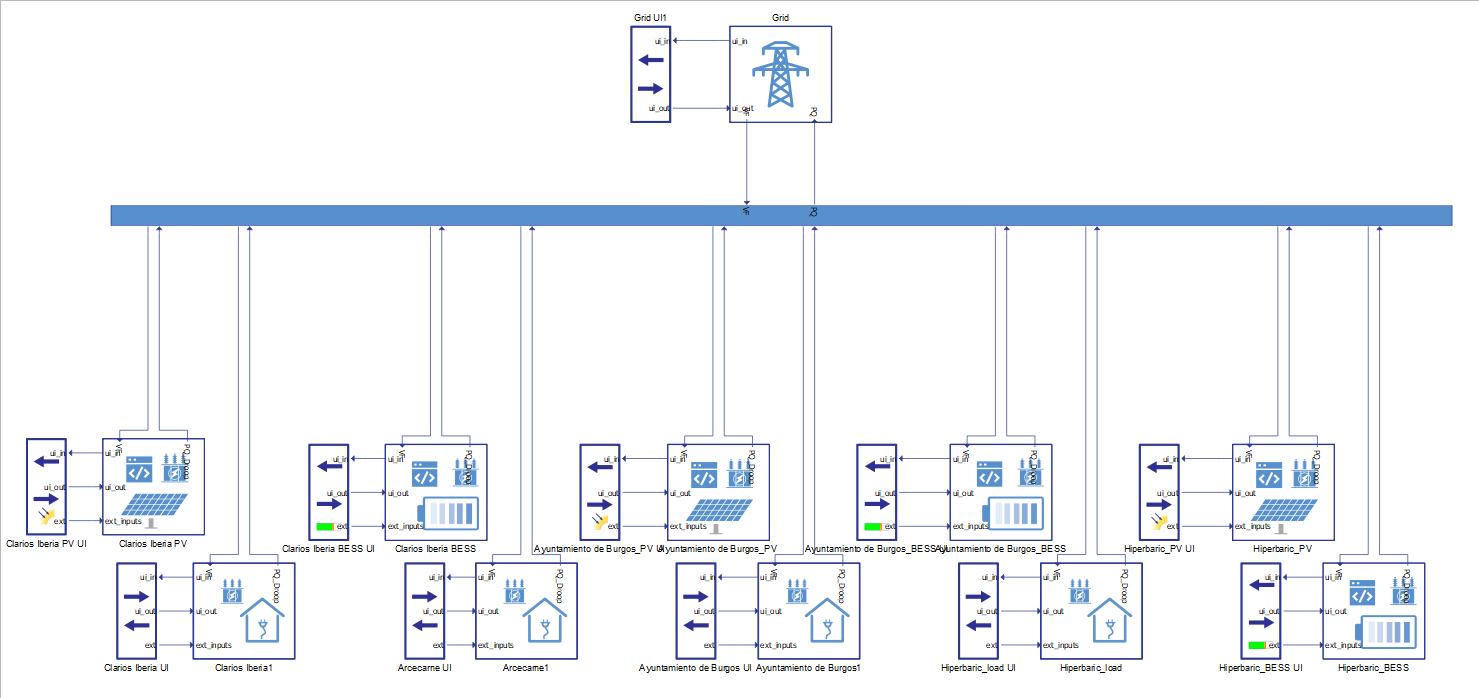

Community Energy System (CES) is a relatively recent development of the distributed generation concept, where local energy assets are integrated to supply a local community with its energy requirements from renewable energy or high-efficiency co-generation energy sources. Typically, a CES can be even considered a microgrid because it comprises multiple generation and storage units that are aggregated, monitored and controlled in order to maximize self-consumption, reduce or completely eliminate energy bills, or even create revenue streams by selling flexibility or ancillary services. As such, every CES is unique in terms of assets and local regulations, and each CES presents both a business development and technical challenge thanks to their novelty and the need to integrate and supervise diverse (renewable) energy assets that previously operated independently. Business-wise, the main challenge is to find the best business case and revenue stream for the respective CES’s combination of assets and local market regulations and possibilities. Technology-wise, the challenge is the integration and management of diverse assets, especially if each asset was previously managed independently by diverse management (e.g. SCADA) systems. Fortunately, digital twins can help with both, dramatically speeding up the process of creating a CES and that is what they are used for in CREATORS where digital twins were created for all tier 1 pilot sites (Acroni, Port of Barcelona, Tartu and Temse), and some tier 2 pilot sites (e.g. Castilla Y Leon).

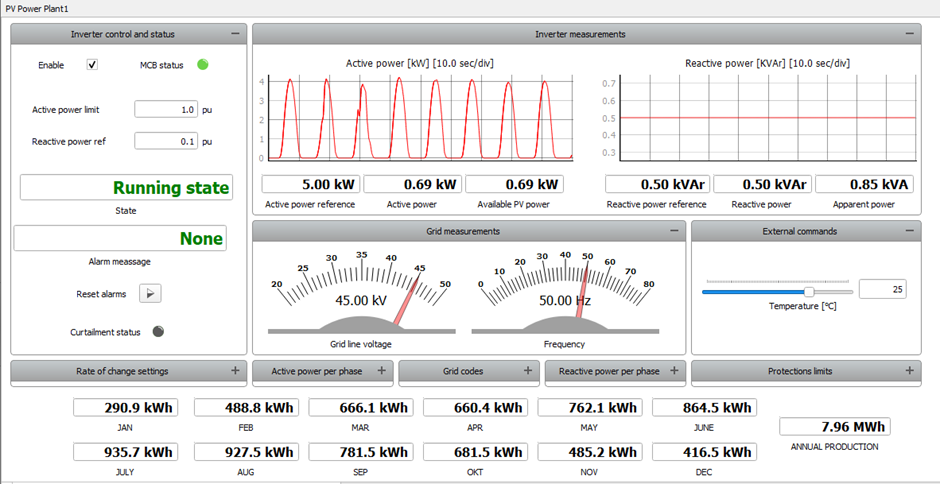

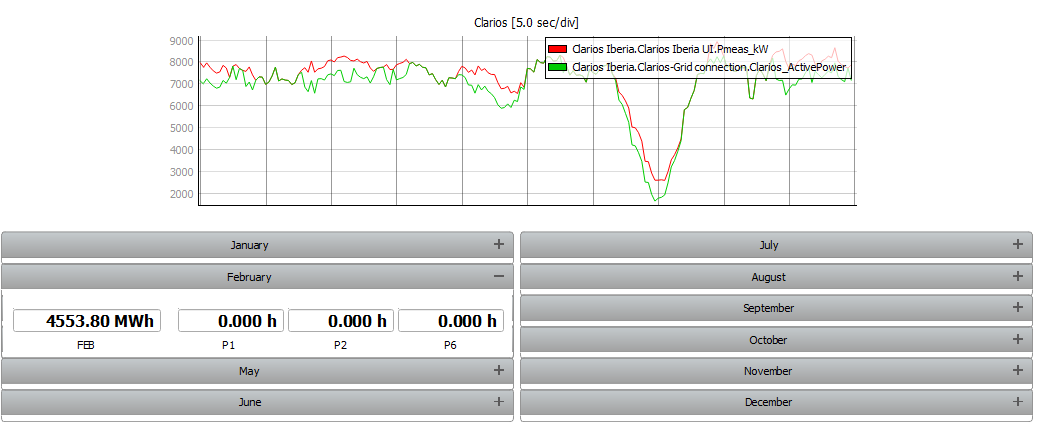

Digital twins de-risk creating Community Energy Systems because they are the only technology which can fully validate, from the operational perspective, the early techno-economic analyses or new revenue stream ideas. More precisely, every techno-economic analysis uses simplified models (sometime even Excel sheets) to estimate capital cost, operating cost, and revenue based on primarily financial input parameters, while technical input parameters usually include only asset capacity, power output and similar generic data that assumes that assets can be controlled and made to perform as expected in any scenario and under any conditions. As the number of distributed energy resources increases, the complexity and challenge of controlling them increases exponentially, as well as the risk of something not working as expected. Most succinctly, good business ideas may seem simple to implement, but simple is not necessarily easy: many projects ultimately fail because techno-economic analyses underestimated or completely ignored the operational challenges. With a digital twin, the techno-economic analysis can be validated not only in standard use cases over days, weeks, or months of operation, but also in edge and emergency scenarios. Furthermore, if the techno-economic analyses or new revenue streams include installation of new assets (e.g. a battery storage system, or PV farm), the digital twin is the perfect to tool to assess the impact of new assets from the financial perspective (e.g. peak shaving, time-of-use optimization, reduction of electricity bills, etc.), but also from the perspective of power quality and the technical performance of the community energy system, ensuring that there will be major issues or voltage and frequency fluctuations.

In addition to de-risking investment decisions for CES by means of operational verification and validation of business models, digital twins also speed-up and streamline CES creation and commissioning. More precisely, when digital twins include the communication layer of all key assets in the CES (e.g. MODBUS registers used by PV inverters, SunSpec maps used by a battery storage system and OCPP profiles of EV chargers), the integration of these assets can be conducted with the digital twin. Once the digital twin is used to solve all integration challenges, such as scaling of measurements and format of command messages, the configuration from the digital twin can just be pushed to the physical CES site: this way the commissioning time can be reduced to a single day.

The same digital twin setup can also be used to integrate future assets and streamline expansion of the asset portfolio in the CES. Firstly, the digital twin of the original CES can be expanded with a generic model of a new asset to verify that its addition will not cause any operational issues. Secondly, the digital twin of the CES with a generic asset model can be modified to contain a precise model of the asset which will be installed, so that, once more, an integration can be done in the digital twin. This way, the downtime of the physical CES is minimal: the configuration from the digital twin just needs to be pushed to the new physical asset.

H2020 HYBRIS | How can digital twins demonstrate the value of novel battery systems?

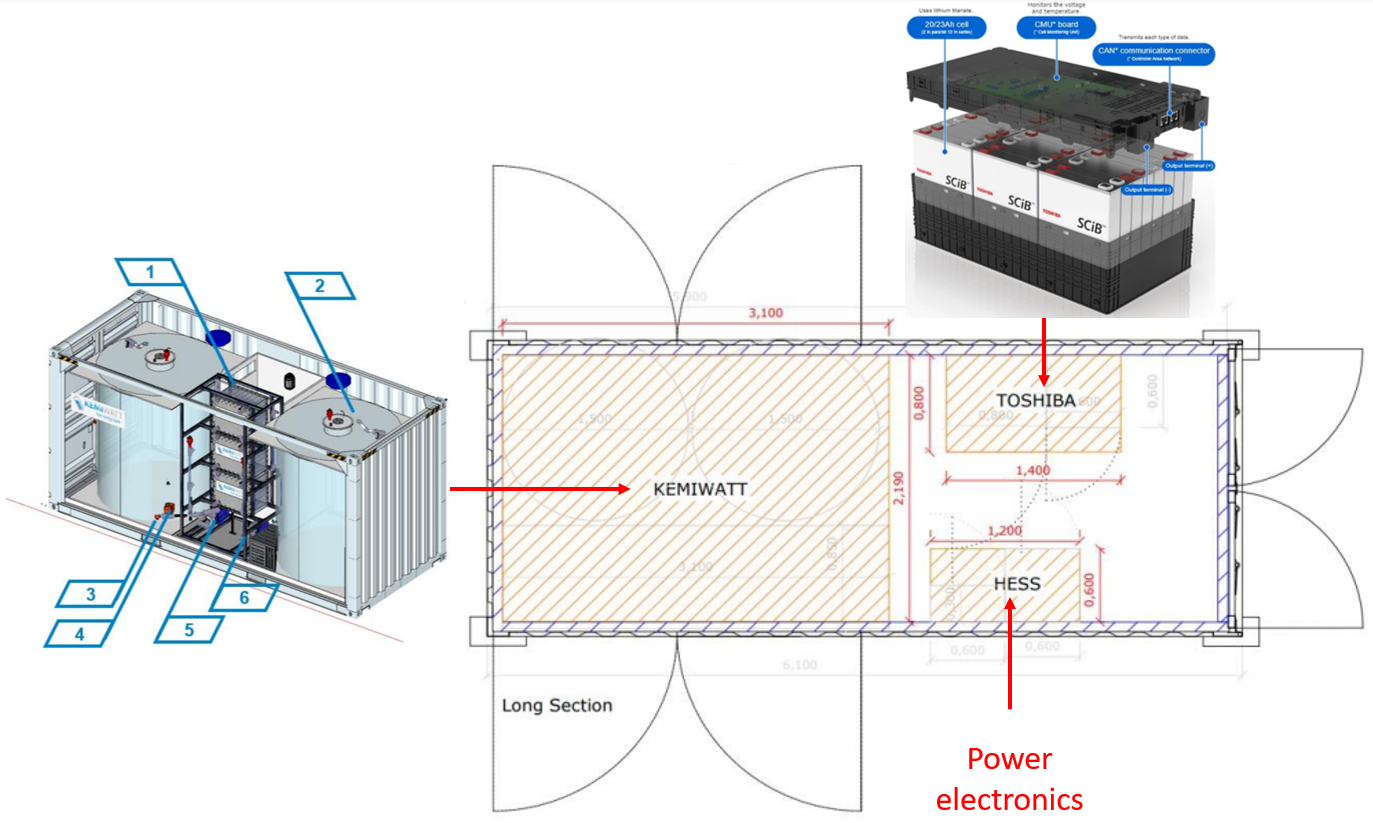

If digital twins are to be widely used, it is important that the modeling framework can be demonstrated in a repeatable and scalable way. In the HYBRIS project, a Toshiba Lithium-Ion battery optimized for power services and a Kemiwatt redox-flow battery optimized for energy services are integrated into a novel hybrid battery system designed to work in a single shipping container, which is moved from partner to partner during the project. To support this, a HIL-based digital twin of the hybrid battery system is developed and validated against real tests to support commissioning and control testing of the real battery prototype. The model is designed with flexible parameters, so that different sizings of the battery systems can be considered over the course of the project.

Once validated, this digital twin of the battery system will be integrated into a digital twin of an Italian grid system managed by Solidarity and Energy. This essentially creates a “virtual demonstration site”, where either the SCADA system on the site or a cloud-based controller can act as the control device under test. Of course, this requires that the site model is properly validated, which will be done in two stages: first, by using the historical and real site data to ensure the control inputs on the site match the simulated behavior in the twin, and second, by replicating the tests performed on the real site with the real battery prototype against those in the fully virtual digital twin environment. Once both validation tests are confirmed, tests on the “virtual demonstration site” can then be performed in advance of real tests, allowing it to act as an operational digital twin of the site.

Lastly, this approach is extended for a residential demonstration site in the Netherlands. Here, no real battery system or local controls will be implemented; instead, a “virtual demonstration site” will be created and validated without the battery asset just as for the Italian site. With the grid digital twin validated, the HYBRIS battery model can also be added virtually, allowing potential users to compare the benefits of the HESS system, and even the performance of different-sized battery systems, using the real conditions of the site itself. This framework has the potential to be a powerful sales tool, making adoption of novel and custom battery systems much more feasible and giving confidence to those that seek to integrate these new technologies that they will work as intended.

Credits

Text | Sergio Costa, Aleksandar Kavgic

Visuals | Karl Mickei, Milica Obradovic

Editor | Debora Santo

The CREATORS and HYBRIS projects have received funding from the European Union’s Horizon 2020 research and innovation program under grant agreement Nos 957815 and 963652, respectively.