Introduction

How can smart inverter manufacturers speed up development without compromising quality?

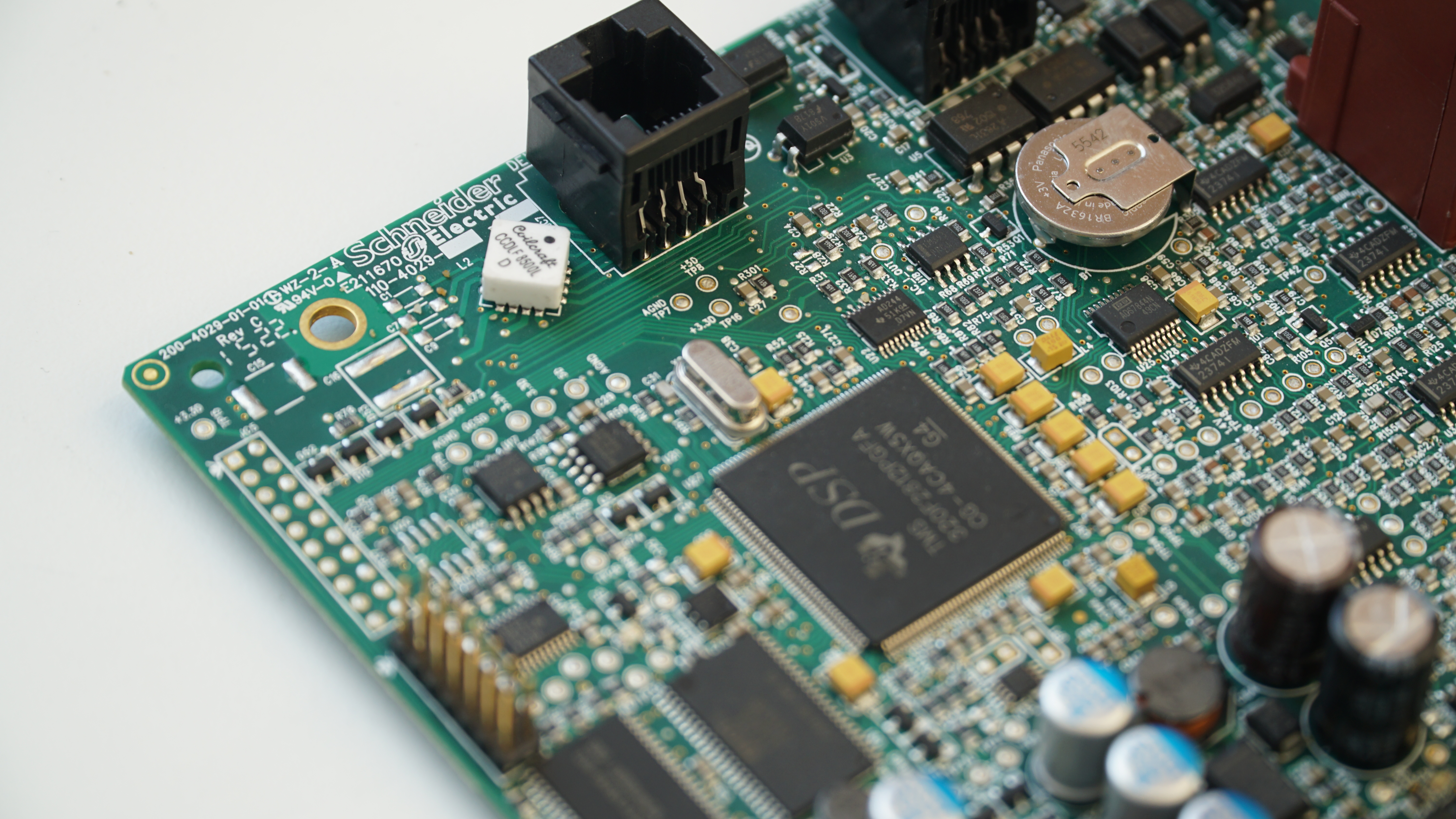

For this next spotlight, we got a chance to speak with Sau Ngosi, CTO of Residential Solar and Storage at Schneider Electric. This division develops cutting-edge solutions for solar power conversion systems.

The Conext XW Pro solar hybrid Inverter/Charger is the latest product that provides the solution for solar with storage, backup power, self-consumption, and off-grid power for homes, small businesses, and remote communities.

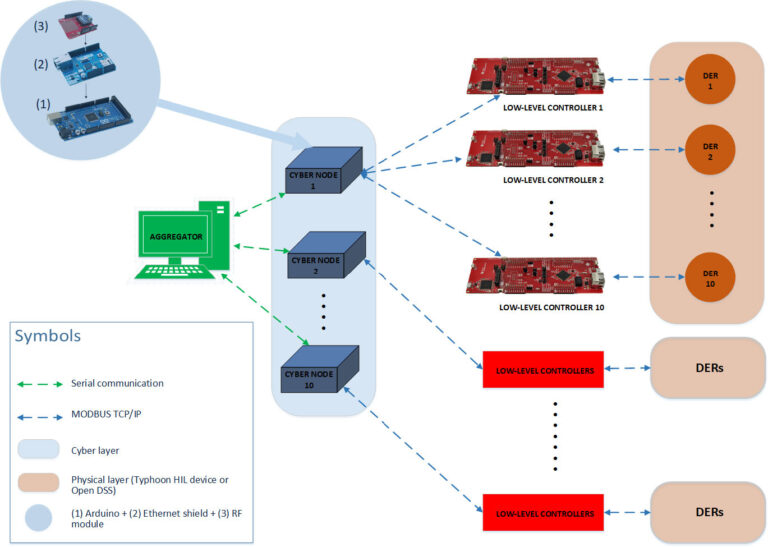

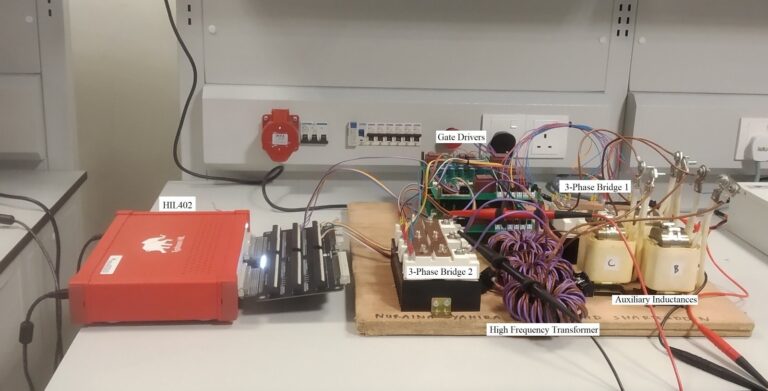

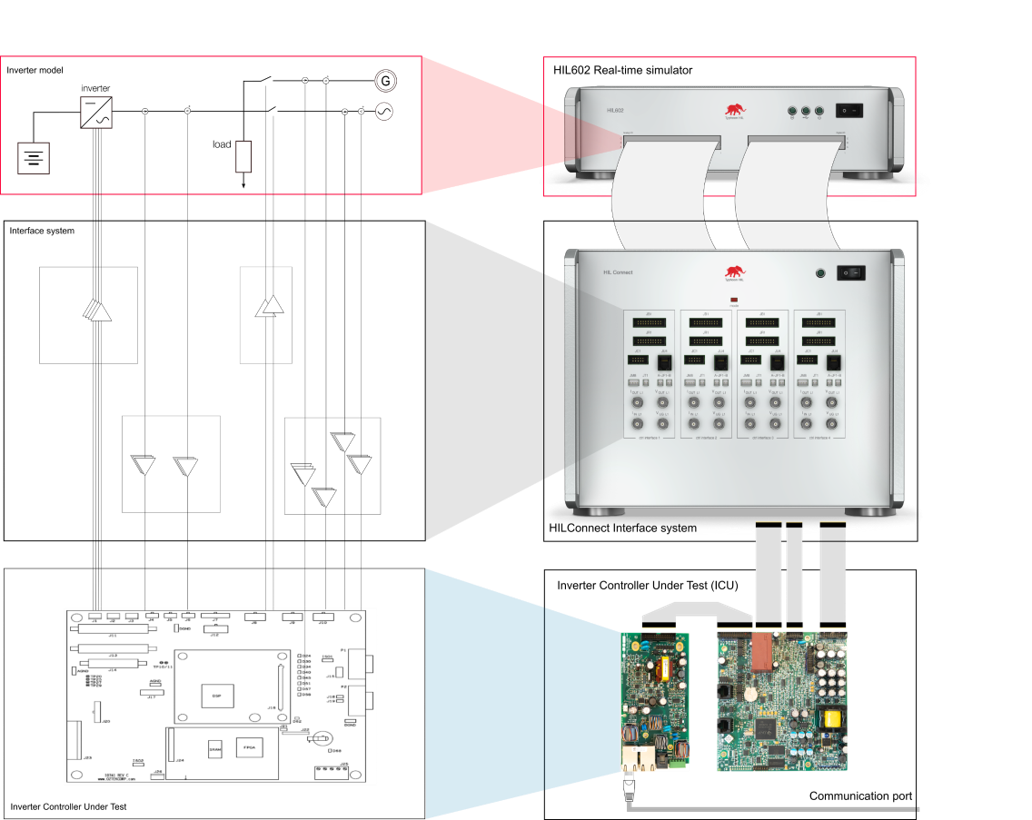

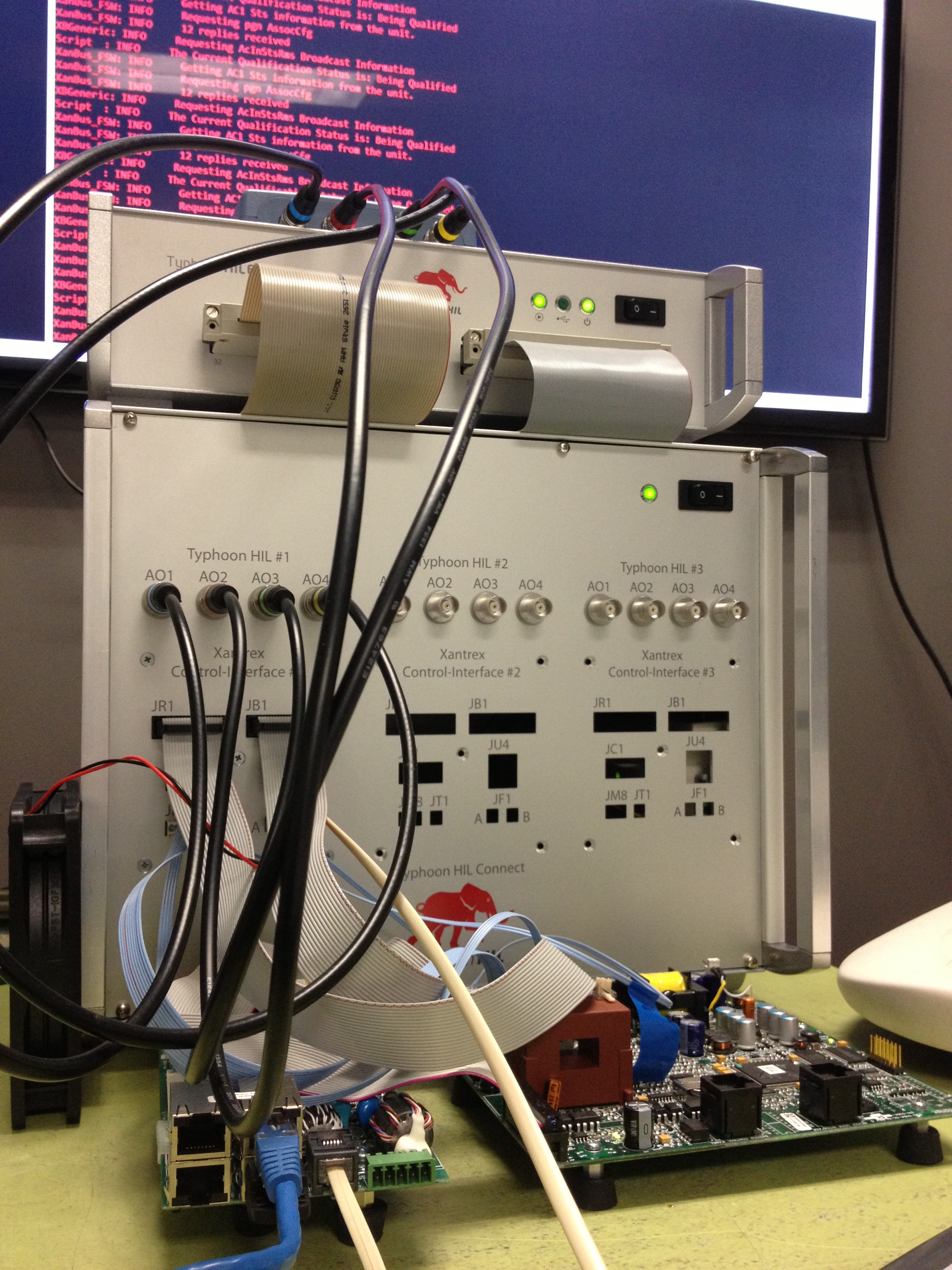

Sau talks about his team’s comprehensive quality assurance process from development to Rule 21 and UL 1741 SA certification using Hardware-in-the-Loop technology (HIL).

Schneider Electric is a global specialist in energy management and automation with over 137,000 employees. It develops connected technologies and solutions to manage energy and processes in ways that are safe, reliable, efficient, and sustainable. The Group invests in R&D to sustain innovation and differentiation, with a strong commitment to sustainable development.

Accelerate Testing without Compromising Quality.

What does “HIL tested” mean for your quality assurance process?

Increasing test coverage and reducing your development times without compromising the quality of the firmware are quality aspects that we feel HIL tested would add to our portfolio of products.

How did a HIL-based system help accelerate Schneider’s development cycle?

In pre-certification, we’ve seen a gain of at least a month because you can go faster from firmware updates to testing that feature set very quickly.

So we’re talking about an approximately fifty percent reduction in the test time.

Expand Test Coverage with Short Test Cycles.

How were you able to increase test coverage with HIL?

Because of the reduction in test cycle times, we’re able to execute more tests in a short period. We are also able to add new test cases with relative ease so it facilitates for easier expansion of the test cases.

In a high-power lab, you must consider whether the test case requires a lab infrastructure update. But in the HIL simulation environment, it might just be an update to your HIL model to add an additional test case.

Can you give me an example of what operating conditions or fault conditions you were able to test with HIL?

A lot of the tests that we focus on are corner cases or grid fluctuations; things that would take a lot of infrastructure to build up and simulate. We do a lot of that type of testing with the HIL.

We also do testing related to fault conditions inside the product that would otherwise be very destructive or would require significant infrastructure updates – short circuit tests are typical tests that we will do on HIL infrastructure.

Reduce the Cost of Investment in High-Power Lab Infrastructure.

How significant is the amount of savings from testing in a HIL environment?

It’s significant when you think about high-power lab infrastructure investment. You must invest in equipment that’s capable of operating at the rated power.

When you’re doing a design on a very high-power inverter, that can be a significant investment in terms of AC sources, DC sources, loads, and infrastructure of that nature.

Whereas with HIL, these are virtualized in a simulation environment, so the savings are significant.

Speed Up the Firmware Release Cycle with Test Automation.

How were you able to automate testing to cover all those test scenarios?

Our approach is to maximize the number of tests that we execute. The fastest way you can do it is by using HIL in an automation environment.

So we make the HIL part of not only the development cycle, we also usually use it quite immensely in the test verification and validation as well.

With HIL, how long did it take to release firmware updates?

We do what we call migration tests where we go through all the operating conditions to test the product and make sure that nothing’s broken.

That could take 2-3 weeks timeline to complete. With HIL, we can finish it end to end within a period of about two days.

HIL is a “Game-Changer”

What’s the one thing that surprised you the most when using a HIL environment?

I think in terms of the big gains was just the fact that we’re able to build such a huge number of test cases and be able to iterate through them in a very short timeline. That was a very big value added for us.

How would you describe HIL in one word?

“Game changer.”

Credits

Author | Samantha Bruce

Visuals | Typhoon HIL

Editor | Debora Santo