Introduction | Powertrain Control Software Development

The development of control software for electric vehicle (EV) powertrain controllers is a complex task, requiring constant modification and testing. Initially, requirements are analyzed to define functionality and performance. Then, the control system architecture is designed, accompanied by interaction specifications with each powertrain component. Finally, the control software undergoes rigorous testing to ensure the safe operation of the controllers. However, waiting until the end of the development process to start testing can lead to increased costs and delayed timelines if any failures are detected then instead of earlier during development. Employing a Model-Based Design (MDB) approach can help you overcome these challenges when dealing with EV powertrain control software development.

Model-Based Design | What are the benefits?

Developing intricate systems such as EV powertrains requires efficient design approaches for top-tier quality and zero bugs. Employing a MBD approach improves efficiency and reduces development time. MBD uses mathematical models to emulate the electric powertrain and verify controllers’ responses during development, thus ensuring reliable testing of the real control system. Furthermore, development teams can collaborate concurrently using the latest model version.

The MBD approach promotes continuous basic testing during the design phase, facilitating early error detection and correction. Consequently, this approach minimizes extensive debugging resulting in substantial time and resource savings. Even so, additional challenges usually arise in control software development, such as ensuring compatibility across different hardware platforms and optimizing system performance by comprehensively accessing all controller parameters.

Control Design and Validation | The Stages of Control Software Development

When developing control software for EV powertrain controllers using the MBD approach, several stages are involved. The first step is gathering requirements and testing the control logic using simulation software with the Model-in-the-Loop (MIL) methodology. Once the control logic has been verified, the next step is to validate the software design using the Software-in-the-Loop (SIL) method. At this stage, the Rapid Control Prototyping (RCP) approach starts to be applied. This involves simulating the controller model on a development computer connected to a digital plant model. It’s a cost-effective way to test the controller’s concept under development without the complexity of testing real controller hardware.

After validating the control software, the controller code is transferred to real-time hardware with input/output interfaces to execute the control strategy effectively. At this stage, generic control hardware may be used since the final hardware, optimized for a specific application, may not be available. After deploying the controller code, simple tests, exposing the controller to open-loop operation and input signal, are executed to validate the hardware response and operation.

When the controller is running smoothly on the hardware, it’s time to test it against the plant. The Hardware-in-the-Loop (HIL) emulates the plant under control, avoiding needing a physical power plant while prototyping the controller. Finally, the control code is executed on a cost-optimized hardware controller while the system continues to be emulated using HIL. These two stages replace the physical plant with a suitable computational model that runs in real-time on the HIL, with inputs and outputs that can interface with the device under test (DUT) and other equipment.

Since testing limitations and late-stage debugging can escalate project costs, identifying and rectifying issues becomes increasingly expensive as development advances. Testing must be rigorous and comprehensive during the entire development process to enable developers to promptly identify and resolve potential issues, minimizing the need for expensive debugging efforts later. Such an approach optimizes resource utilization and guarantees the delivery of high-quality control software for EV powertrain controllers.

The Industry Perspective | Cutting-Edge Technology Available on the Market

For optimal product development, you must have superior hardware and supporting solutions. Infineon, Vector, and Typhoon HIL offer cutting-edge and sophisticated development tools that reduce design time and costs and ensure that the quality and reliability of your solutions are maintained at the highest levels.

Infineon AURIX™ TC3xx automotive MCUs

Infineon is the market leader in supplying chips for MCUs. One example is the AURIX™-TC3xx microcontroller family. They offer high-performance architecture up to hexacore, advanced connectivity, safety, and functional protection features, making them ideal for various automotive applications. The AURIX™-TC3xx family concept also offers scalable feature sets and pinouts for optimal flexibility while meeting ASIL-D requirements.

Based on the 32-bit TriCore™ processor architecture, the AURIX™-TC3xx balances real-time performance and power efficiency, offering a range of performance options from single-core to multi-core variants, enabling scalability and design flexibility. These MCUs are suitable for EV applications in electric and hybrid drive systems, such as hybrid control units, inverter control in HEVs and BEVs, battery management, DC-DC chargers and converters, and motor management systems.

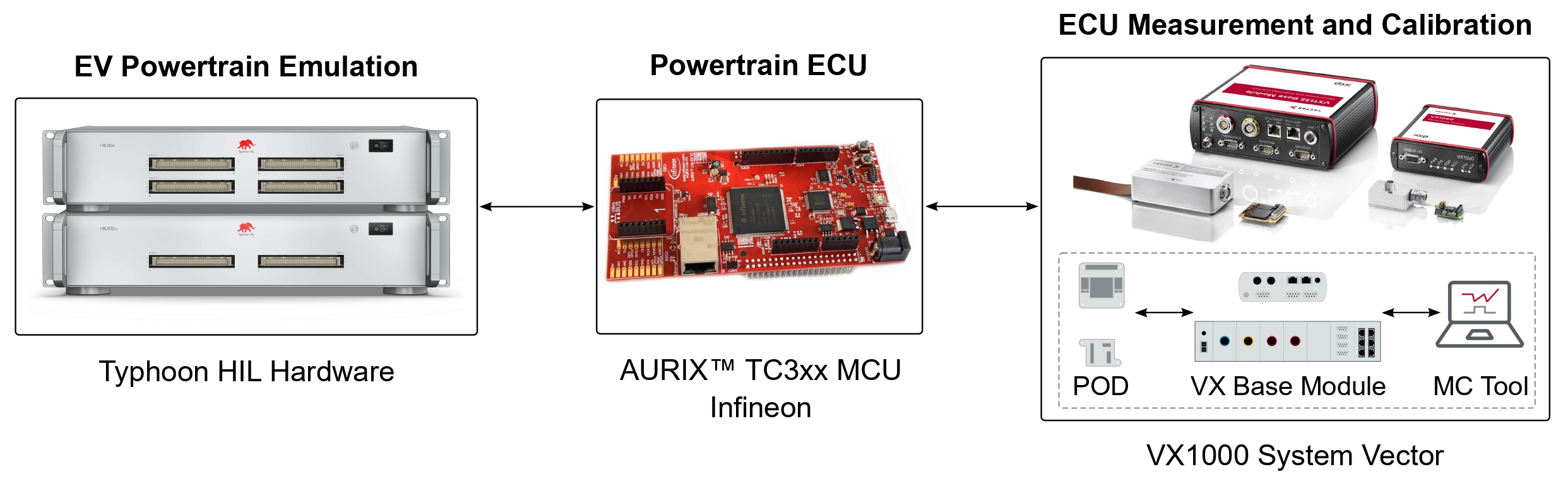

Vector’s VX1000 System

Vector’s VX1000 system delivers a scalable, high-performance solution for ECU measurement and calibration tasks. It can be seamlessly utilized in vehicles, test benches, and laboratories. The system empowers precise control over raw data captured by high-resolution radar sensors complemented by XCP data.

As an interface between the ECU and measurement and calibration tools, the VX1000 grants rapid access to internal ECU data, facilitating higher transmission rates. Its connectivity to the PC via XCP on Ethernet, an extensively employed automotive industry standard, ensures smooth integration.

The VX1000 boasts numerous advantages, including compact device size for ECU debug interface connection, galvanic isolation of modules and devices, extensive support for diverse ECU connectors via adapters, and effortless integration into ECU software. These attributes collectively position the VX1000 as a comprehensive and efficient solution that readily addresses the demanding requirements of ECU measurement and calibration in the automotive industry.

Typhoon HIL Ultra High-Fidelity HIL

Typhoon HIL’s high-fidelity emulator accurately tests systems using advanced hardware and software. The HIL approach allows controller testing before physical prototypes are built, enabling different test conditions and verifying behavior in the face of disturbances and faults.

Typhoon HIL hardware offers a powerful and flexible emulation platform that reproduces electrical and dynamic characteristics of complex systems through ultra-high fidelity models with a wide range of interfacing and connectivity options. In addition, with Typhoon HIL’s vertically integrated software, you can create virtual models of real systems, making it possible to create digital twins that accurately reproduce the physical system’s behavior.

Utilizing digital twins allows engineers to test their designs in various conditions, including faults, variations, and transient events. Furthermore, Typhoon HIL solutions include access to automated testing. This allows you to create complex test scenarios and repeatable test cycles for each code revision. This saves time and resources while providing significant benefits such as accelerated test cycles, increased test coverage, and improved reliability. As a result, you can achieve higher product quality and faster time to market.

HIL Benefits | Streamline EV Powertrain Controller Development with Typhoon HIL

To develop cutting-edge solutions for EV powertrains, you need a cutting-edge processor and testing devices to streamline the control development. Infineon provides a powerful, high-quality MCU that realizes the requirements to develop robust EV solutions.

By using Typhoon HIL and Vector for testing, you can count on having a platform to relentlessly test the controllers against different scenarios and ensure the robust and reliable operation of the powertrain. Using the Typhoon HIL solution, you can expose the high-performance Infineon hardware and your software to real events replicated with high fidelity. As a result, your controller is put through to a wide range of operational scenarios and faults, making it possible to validate DUT behavior as close as possible to tests with production hardware. Automated tests can evaluate the controller seamlessly after each update or new feature. In addition, new tests can be included continuously to expand the testing coverage without adding costs to hardware testing. Besides automating your tests, you can also report them automatically, generating reliable documentation of your development process.

With the Typhoon HIL platform, you can expose the MCU to different test scenarios, with the control code already running on Infineon’s physical hardware. However, to verify exactly how the EV powertrain controller is performing, it is necessary to have access not only to the system outputs but also to the internal states of the controller while the tests are running. Therefore, you can use Vector’s VX1000 solution to access the ECU’s internal data and understand in depth how the controller reacts to each test scenario it is subjected to. The VX1000 system makes it possible to read and send data to the EV powertrain ECU, which allows the measurement of the controller’s internal states and the calibration necessary to optimize the operation of the control software.

Combining Infineon, Vector, and Typhoon HIL solutions is a great way to develop and test control software for EV powertrain controllers. This approach saves time and money and guarantees reliable and robust performance.

Credits

Authors | Cassiano F. Moraes, Heitor J. Tessaro, Gustavo Bruinsma

Editors | Boris Jovanovic, Petar Gartner, Debora Santo

Visuals | Gustavo Bruinsma, Heitor J Tessaro, Milica Obradovic